Active vocabulary

Date: 2015-10-07; view: 701.

Unit 2. Well Сompletion

C. Discussion

Topics:

1) Types of casing.

2) Well casing installation.

| 1. | completion | (зд) установка эксплуатационного оборудования |

| 2. | conventional perforated completion | заканчивание скважины с перфорируемой эксплуатационной колонной |

| 3. | sand exclusion completion | заканчивание скважины с удалением песка |

| 4. | permanent completion | заканчивание скважины со стационарным оборудованием |

| 5. | multiple zone completion | многопластовое заканчивание скважины (для одновременной эксплуатации нескольких продуктивных горизонтов) |

| 6. | drainhole completion | заканчивание разветвленной скважины, многозабойное заканчивание скважины |

| 7. | openhole completion | заканчивание скважины с необсаженным забоем |

| 8. | blowout | фонтанирование скважины |

| 9. | casing head | головка обсадной колонны |

| 10. | tubing head | трубная головка |

| 11. | wellhead | устье скважины; устьевая арматура |

| 12. | valve | задвижка, клапан |

| 13. | screen/filter | сетчатый фильтр |

| 14. | perforation | перфорация |

| 15. | jet perforating | простреливание с помощью кумулятивного перфоратора |

| 16. | jet perforator charge | торпеда, снаряженная кумулятивным зарядом для перфорирования скважины |

| 17. | fitting | соединительная деталь трубопровода |

| 18. | heavy fittings/pipe fitting | тяжелая арматура |

| 19. | seal | прокладка/изолирующий слой |

| 20. | sand screening | отделение/просеивание песка |

| 21. | producing stratum | продуктивный пласт |

| 22. | collapse | обрушение |

| 23. | sandface | вскрытая поверхность (забоя и стенок скважины) в песчаном пласте |

| 24. | сhristmas tree | фонтанное устьевое оборудование/ фонтанная арматура |

| 25. | blowout preventer (BOP) | противовыбросовый превентор (клапан) |

| 26. | acid /hydraulic fracturing of formation | кислотный/гидравлический разрыв пласта |

| 27. | loose sand | рыхлый песок/песчаный грунт |

| 28. | oil-well screen | фильтр для нефтяной скважины |

| 29. | heavy fittings/pipe fitting | тяжелая арматура |

| 30. | to withstand | выдерживать, не поддаваться чему-либо |

| 31. | to cave in | проседать (о скважине); обрушиваться в выработку |

| 32. | to case off | изолировать с помощью обсадной колонны |

| 33. | to control the flow of the oil | контролировать/управлять потоком нефти |

| 34. | to keep smth out | не допускать проникновения |

| 35. | to complete a well | заканчивать скважину |

| 36. | to be monted at smth | устанавливаться на что-либо |

Well completion commonly refers to the process of finishing a well so that it is ready to produce oil or natural gas. In essence, completion consists of deciding on the characteristics of the intake portion of the well in the targeted hydrocarbon formation. There are a number of types of completions, including: openhole completion, conventional perforated completion, sand exclusion completion, permanent completion, multiple zone completion, drainhole completion.

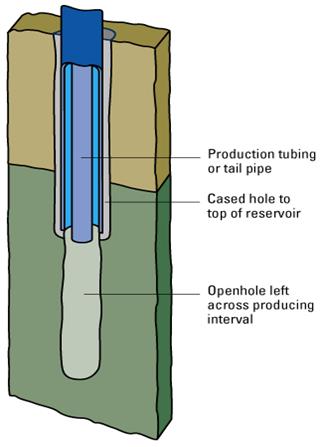

The use of any type of completion depends on the characteristics and location of the hydrocarbon formation to be mined. Openhole completions are the most basic type and are only used in very competent formations, which are unlikely to cave in.

An openhole completion consists of simply running the casing directly down into the formation, leaving the end of the piping open, without any other protective filter. Very often, this type of completion is used on formations that have been treated with hydraulic or acid fracturing.

Conventional perforated completions consist of production casing being run through the formation. The sides of this casing are perforated, with tiny holes along the sides facing the formation, which allows for the flow of hydrocarbons into the well hole, but still provides a suitable amount of support and protection for the well hole.

Conventional perforated completions consist of production casing being run through the formation. The sides of this casing are perforated, with tiny holes along the sides facing the formation, which allows for the flow of hydrocarbons into the well hole, but still provides a suitable amount of support and protection for the well hole.

The process of actually perforating the casing involves the use of specialized equipment designed to make tiny holes through the casing, cementing, and any other barrier between the formation and the open well. Jet perforating is used today. This consists of small, electrically ignited charges, lowered into the well. When ignited, these charges poke tiny holes through to the formation.

| Fig.1 Openhole completion |

Sand exclusion completions are designed for production in an area that contains a large amount of loose sand. These completions are designed to allow for the flow of natural gas and oil into the well, but at the same time prevent sand from entering the well. Sand inside the well hole can cause many complications, including erosion of casing and other equipment. The most common method of keeping sand out of the well hole are screening, or filtering systems. This includes analyzing the sand experienced in the formation and installing a screen or filter to keep sand particles out.

Permanent completions are those in which the completion, and wellhead, are assembled and installed only once. Installing the casing, cementing, perforating, and other completion work is done with small diameter tools to ensure the permanent nature of the completion. Completing a well in this manner can lead to significant cost savings compared to other types.

Multiple zone completion is the practice of completing a well such that hydrocarbons from two or more formations may be produced simultaneously, without mixing with each other. For example, a well may be drilled that passes through a number of formations on its way deeper underground, or alternately, it may be efficient in a horizontal well to add multiple completions to drain the formation most effectively. Although it is common to separate multiple completions so that the fluids from the different formations do not intermingle, the complexity of achieving complete separation is often a barrier.

Drainhole completions are a form of horizontal or slant drilling. This type of completion consists of drilling out horizontally into the formation from a vertical well, essentially providing a 'drain' for the hydrocarbons to run down into the well. In certain formations, drilling a drainhole completion may allow for more efficient and balanced extraction of the targeted hydrocarbons. These completions are more commonly associated with oil wells than with natural gas wells.

The wellhead consists of the pieces of equipment mounted at the opening of the well to regulate and monitor the

|

| Fig. 2 Wellhead |

extraction of hydrocarbons from the underground formation. It also prevents leaking of oil or natural gas out of the well, and prevents blowouts due to high pressure formations. Formations that are under high pressure typically require wellheads that can withstand a great deal of upward pressure from the escaping gases and liquids. These wellheads must be able to withstand pressures of up to 20,000 psi (pounds per square inch). The wellhead consists of three components: the casing head, the tubing head, and the 'christmas tree'.

The casing head consists of heavy fittings that provide a seal between the casing and the surface. The casing head also serves to support the entire length of casing that is run all the way down the well.

The tubing head is much like the casing head. It provides a seal between the tubing, which is run inside the casing, and the surface. Like the casing head, the tubing head is designed to support the entire length of the casing, as well as provide connections at the surface, which allow the flow of fluids out of the well to be controlled.

The 'Christmas tree' is the piece of equipment that fits atop the casing and tubing heads, and contains tubes and valves that serve to control the flow of hydrocarbons and other fluids out of the well. It commonly contains many branches and is shaped somewhat like a tree, thus its name, Christmas tree. The Christmas tree is the most visible part of a producing well, and allows for the surface monitoring and regulation of the production of hydrocarbons from a producing well.

| <== previous lecture | | | next lecture ==> |

| B. Vocabulary practice | | | B. Vocabulary practice |