Active vocabulary

Date: 2015-10-07; view: 660.

Unit 3. Cementing

C. Discussion

Topics:

1. Different types of well completion.

2. Explain the difference between openhole completion, conventional perforated completion, sand exclusion completion, multiple zone completion. Illustrate your explanation with some examples.

| 1. | slurry | жидкий цементный раствор |

| 2. | pump | насос |

| 3. | float collar | обратный клапан; муфта обсадной трубы с обратным клапаном |

| 4. | rubber plug/ bottom plug | пробка на забое |

| 5. | cementing head/plug container | головка для сбрасывания (цементировочных) пробок |

| 6. | guide shoe/cement float shoe | направляющий бамак/башмачная насадка с обратным клапаном (для цементирования скважины) |

| 7. | annular space | кольцевое /межтрубное пространство (в буровой скважине) |

| 8. | displacement fluid | буферная жидкость |

| 9. | remedial procedures /remedial cementing | методика устранения неисправностей |

| 10. | squeeze cementing | цементирование под давлением; исправительный тампонаж |

| 11. | corrosive formation fluids | агрессивные пластовые воды |

| 12. | to bond | связывать; соединять; сцеплять |

| 13. | to mix / to blend smth with smth | смешивать что-то с чем-либо |

| 14. | to mount | монтировать, устанавливать |

| 15. | to release a plug | освобождать/вынимать пробку |

| 16. | to bump a well | ударять насосом по дну скважины |

| 17. | to shut down | выключать; останавливать |

| 18. | to pump | подавать/нагнетать насосом; прокачивать (буровой раствор) |

| 19. | to harden | становиться твердым, застывать |

| 20. | to hire а cementing crew | нанимать на работу цементировочную бригаду |

| 21. | to run tests | проводить исследования/тесты |

| 22. | to alleviate /eliminate (the problem) | устронять(проблему/неисправность) |

| 23. | to rectify | исправлять (ошибки), поправлять (ситуацию) |

| 24. | WOC ("waiting on cement") | время, необходимое для застывания цемента |

Cement bonds the casing to the hole and prevents fluids in one formation from migrating to another. Cement also prevents corrosive formation fluids from damaging the casing.

The operator usually hires an oil well cementing company to perform the job. Cementing companies stock many kinds of cement and have special equipment to transport it to the well. At the well, the company mixes the dry cement with water to form slurry - a thin, watery mixture that is easy to pump. Many kinds of mixers are available to blend the water and cement into a uniform mixture as the cement pumps move it down the casing.

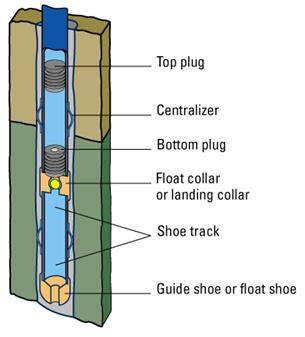

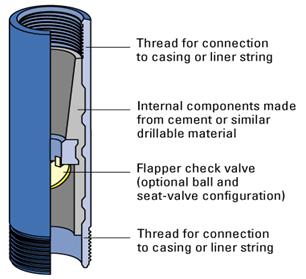

Special high-pressure pumps move the slurry through very strong pipes, or lines, to a cementing head, or plug container. Earlier, the cementing crew mounted the cementing head on the topmost joint of casing hanging in the mast or derrick. Just before the slurry arrives at the head, a crew member releases a rubber plug, a bottom plug, from the cementing head. The bottom plug separates the cement slurry from any drilling fluid inside the casing and prevents the mud from contaminating the cement. The slurry moves the bottom plug down the casing. The plug stops, or seats, in the float collar. Continued pumping breaks a membrane on the bottom plug and opens a passage. Slurry then goes through the bottom plug and continues down the last few joints of casing. It flows through an opening in the guide shoe and up the annular space between the casing and the hole. Pumping continues until the slurry fills the annular space.

Special high-pressure pumps move the slurry through very strong pipes, or lines, to a cementing head, or plug container. Earlier, the cementing crew mounted the cementing head on the topmost joint of casing hanging in the mast or derrick. Just before the slurry arrives at the head, a crew member releases a rubber plug, a bottom plug, from the cementing head. The bottom plug separates the cement slurry from any drilling fluid inside the casing and prevents the mud from contaminating the cement. The slurry moves the bottom plug down the casing. The plug stops, or seats, in the float collar. Continued pumping breaks a membrane on the bottom plug and opens a passage. Slurry then goes through the bottom plug and continues down the last few joints of casing. It flows through an opening in the guide shoe and up the annular space between the casing and the hole. Pumping continues until the slurry fills the annular space.

As the last of the cement slurry enters the casing, a crew member releases a top plug from the cementing head. A top plug is like a bottom plug except that it has no membrane or passage. The top plug separates the last of the cement to go into the casing from displacement fluid. Displacement fluid, which is usually salt water or a specially formulated drilling mud, moves, or displaces, the cement from the casing as the cement pump applies pressure to move the cement and fluid down the casing.

As the last of the cement slurry enters the casing, a crew member releases a top plug from the cementing head. A top plug is like a bottom plug except that it has no membrane or passage. The top plug separates the last of the cement to go into the casing from displacement fluid. Displacement fluid, which is usually salt water or a specially formulated drilling mud, moves, or displaces, the cement from the casing as the cement pump applies pressure to move the cement and fluid down the casing.

Continued pumping moves the cement, the top plug, and the displacement fluid down the casing. Most of the cement slurry flows out of the casing and into the annular space. Soon, the top plug seats on, or bumps, the bottom plug in the float collar. When it bumps, the pump operator shuts down the pumps. Cement is only in the casing below the float collar and in the annular space. Most of the casing is fall of displacement fluid.

After the cement company pumps the cement and removes its equipment, the operator and drilling contractor wait a specified time for the cement to harden. This period is referred to as "waiting on cement" or simply WOC. WOC can vary from a few hours to several, depending on the cement formulation, well temperature, and other factors.

After the cement hardens, the operator usually runs tests to ensure that the cement job is satisfactory. If it is, then crew members can get back to drilling. If it is not, the cementing company uses special remedial procedures to alleviate the problem. Remedial cementing involves determining the depth of the problem and then, by using special equipment, placing cement at that depth to rectify it.

| <== previous lecture | | | next lecture ==> |

| B. Vocabulary practice | | | B. Vocabulary practice |